|

Jingqiu Magnetic Electric Co.,LTD

|

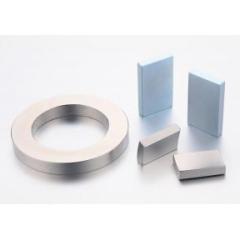

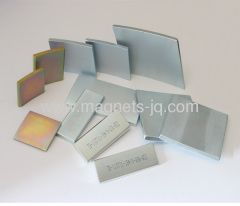

N35 N38 N40 N42 N45 N48 N50 N52 Block Permanent NdFeB /NeodymiumMagnet

| Price: | 0.1~10.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

N52 Gold/Au coating Block NdFeB Magnet

Neodymium magnet (Nd-Fe-B) is one of the highest property and strongest permanent magnet by now, are made through powder metallurgy manufacturing techniques. They are mainly composed of neodymium(32%), iron(64%), boron(1%), and a few quantity rare earth material, such as Dy, Tb, Co, Nb, Ga, Al, Cu, etc.

Neodymium magnet is regarded as "Magnet King" due to its recorded high performance, coercive force and maximum energy product. With Neodymium magnet rapid development, many high-tech products were developed. Especially its application in mmakes products miniaturization and micromation.

At the same time, because of its high performance,coercive force and maximum energy product, this type magnet is widely used in servo motor, flat brushless motor, step motor, IT products, Nuclear Magnetic Resonance, speaker and other products. Neodymium magnet is easily rust and oxidated, so their surface must be plated Zn, Ni, Silver, Gold or made phosphor and epoxy treatment.

Our company has advanced scientific research and production equipments, strictly following ISO9001 Quality Management System to manufacture. We continuously strengthen inner management. From melting, milling, sinter and then process, all the working procedure are very perfect. The manufacturing technique are excellent. We can supply various dimension neodymium magnets with high property and enduring high temperature. The mainly higher product Grade is N45, N48, N50, N52, 48M, 50M, 44H, 46H, 48H, 42SH, 44SH, 38UH, 40UH, 33EH, 35EH.

Main Application Fields of NdFeB Magnet

Sonic Equipment:Earphone, Microphone, Loudspeaker.

Apparatus: Electricity Meter, Velometer, Flow-meter, Tachometer.

Medical Device:Magnetic Resonance Image Device, Water Magnetizer, Magnetic Therary Device.

Micro motor and special motor: Voice Coil Motor(VCM), Step Motor,Texture Motor, Geared down Motor, Disk Motor, Servo Motor, and Permanent-Dynamic System.

Industry installation:Magnetic Clamp, Magnetic Crane/Magnetic Lift, Magnetize Filter, CD-ROM, petrol dewaxing Equipment, Magnetic Coupler, Magntic Switch, Generator, Magnetic Separator.

Sonic Equipment:Earphone, Microphone, Loudspeaker.

Apparatus: Electricity Meter, Velometer, Flow-meter, Tachometer.

Medical Device:Magnetic Resonance Image Device, Water Magnetizer, Magnetic Therary Device.

Micro motor and special motor: Voice Coil Motor(VCM), Step Motor,Texture Motor, Geared down Motor, Disk Motor, Servo Motor, and Permanent-Dynamic System.

Industry installation:Magnetic Clamp, Magnetic Crane/Magnetic Lift, Magnetize Filter, CD-ROM, petrol dewaxing Equipment, Magnetic Coupler, Magntic Switch, Generator, Magnetic Separator.

Magnetic properties of Neodymiummagnets

| Grade | Br | Hcb | Hcj | (BH)max | Density | Curie Temp | Working Temp | ||||

| mT | kGs | kA/m | kOe | kA/m | kOe | kJ/m3 | MGOe | g/cm3 | ℃ | ℃ | |

| N35 | 1180-1230 | 11800-12300 | ≥868 | ≥10900 | ≥955 | ≥12000 | 263-287 | 33-36 | 7.45 | 310 | ≤80 |

| N38 | 1220-1280 | 12200-12800 | ≥899 | ≥11300 | ≥955 | ≥12000 | 287-310 | 36-39 | |||

| N40 | 1250-1310 | 12600-13100 | ≥923 | ≥11600 | ≥955 | ≥12000 | 302-326 | 38-41 | |||

| N42 | 1280-1340 | 12800-13400 | ≥923 | ≥11600 | ≥955 | ≥12000 | 318-342 | 40-43 | |||

| N45 | 1320-1370 | 13200-13700 | ≥876 | ≥11000 | ≥955 | ≥12000 | 342-366 | 43-46 | |||

| N48 | 1380-1420 | 13600-14200 | ≥836 | ≥10500 | ≥876 | ≥11000 | 358-390 | 45-48 | |||

| N50 | 1400-1450 | 13900-14500 | ≥836 | ≥10500 | ≥876 | ≥11000 | 374-406 | 47-51 | |||

| N52 | 1430-1480 | 14200-14800 | ≥796 | ≥10000 | ≥876 | ≥11000 | 390-422 | 49-53 | |||

| N35M | 1180-1230 | 11800-12300 | ≥868 | ≥10900 | ≥1114 | ≥14000 | 263-287 | 33-36 | ≤100 | ||

| N38M | 1220-1280 | 12200-12800 | ≥899 | ≥11300 | ≥1114 | ≥14000 | 287-310 | 36-39 | |||

| N40M | 1260-1310 | 12600-13100 | ≥923 | ≥11600 | ≥1114 | ≥14000 | 302-326 | 38-41 | |||

| N42M | 1280-1340 | 12800-13400 | ≥923 | ≥11600 | ≥1114 | ≥14000 | 318-342 | 40-43 | |||

| N45M | 1340-1390 | 13400-13900 | ≥876 | ≥11000 | ≥1114 | ≥14000 | 342-366 | 43-46 | |||

| N48M | 1360-1420 | 13600-14200 | ≥876 | ≥11000 | ≥1114 | ≥14000 | 366-390 | 46-49 | |||

| N35H | 1180-1230 | 11800-12300 | ≥868 | ≥10900 | ≥1353 | ≥17000 | 263-287 | 33-36 | ≤120 | ||

| N38H | 1220-1280 | 12200-12800 | ≥899 | ≥11300 | ≥1353 | ≥17000 | 287-310 | 36-39 | |||

| N40H | 1260-1310 | 12600-13100 | ≥923 | ≥11600 | ≥1353 | ≥17000 | 302-326 | 38-41 | |||

| N42H | 1280-1340 | 12800-13400 | ≥923 | ≥11600 | ≥1353 | ≥17000 | 318-342 | 40-43 | |||

| N45H | 1330-1390 | 13300-13900 | ≥923 | ≥11600 | ≥1353 | ≥17000 | 342-366 | 43-46 | |||

| N48H | 1360-1420 | 13600-14200 | ≥923 | ≥11600 | ≥1274 | ≥16000 | 366-390 | 46-49 | |||

| N33SH | 1140-1190 | 11400-11900 | ≥836 | ≥10500 | ≥1592 | ≥20000 | 247-270 | 31-34 | ≤150 | ||

| N35SH | 1180-1230 | 11800-12300 | ≥868 | ≥10900 | ≥1592 | ≥20000 | 263-287 | 33-36 | |||

| N38SH | 1220-1280 | 12200-12800 | ≥899 | ≥11300 | ≥1592 | ≥20000 | 287-310 | 36-39 | |||

| N40SH | 1260-1310 | 12600-13100 | ≥923 | ≥11600 | ≥1592 | ≥20000 | 302-326 | 38-41 | |||

| N42SH | 1280-1340 | 12800-13400 | ≥923 | ≥11600 | ≥1592 | ≥20000 | 318-342 | 40-43 | |||

| N45SH | 1330-1390 | 13300-13900 | ≥923 | ≥11600 | ≥1592 | ≥20000 | 342-366 | 43-46 | |||

| N28UH | 1030-1090 | 10300-10900 | ≥780 | ≥9800 | ≥1990 | ≥25000 | 207-231 | 26-29 | ≤180 | ||

| N30UH | 1090-1140 | 10900-11400 | ≥812 | ≥10200 | ≥1990 | ≥25000 | 223-247 | 28-31 | |||

| N33UH | 1130-1170 | 11300-11700 | ≥852 | ≥10700 | ≥1990 | ≥25000 | 247-263 | 31-33 | |||

| N35UH | 1180-1220 | 11800-12200 | ≥868 | ≥10900 | ≥1990 | ≥25000 | 263-287 | 33-36 | |||

| N38UH | 1220-1270 | 12200-12700 | ≥899 | ≥11300 | ≥1990 | ≥25000 | 287-310 | 36-39 | |||

| N28EH | 1030-1090 | 10300-10900 | ≥780 | ≥9800 | ≥2388 | ≥30000 | 207-231 | 26-29 | ≤200 | ||

| N30EH | 1080-1130 | 10800-11300 | ≥812 | ≥10200 | ≥2388 | ≥30000 | 223-247 | 28-31 | |||

| N33EH | 1130-1170 | 11300-11700 | ≥852 | ≥10700 | ≥2388 | ≥30000 | 247-263 | 31-33 | |||

| N35EH | 1180-1220 | 11800-12200 | ≥868 | ≥10900 | ≥2388 | ≥30000 | 263-287 | 33-36 | |||

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Ndfeb N35 Magnet

Permanent Ndfeb

Ndfeb Block

Ndfeb Permanent Magnet

Permanent Ndfeb Magnets

Sintered Ndfeb Permanent Magnet

More>>